Automation Systems for Respiratory Devices

Topics:

November 2025

Across the healthcare world, respiratory devices save lives every day. From inhalers and nebulisers to powder-based delivery systems, these technologies depend on precision at a microscopic scale. Every seal, every fill, every assembly step must perform flawlessly because people’s health depends on it.

For SP Automation & Robotics, respiratory automation is far more than an engineering challenge. It is a responsibility. The company has decades of experience designing and building automation systems that assemble, fill and package respiratory products with the accuracy and reliability that medical manufacturing demands. From powder filling to canister removal, from final packaging to inspection, SP’s systems deliver the highest standards of quality and repeatability, ensuring every device that reaches a patient is safe, compliant and consistent.

The Complexity of Respiratory Device Manufacturing

Respiratory products such as metered-dose inhalers, dry powder inhalers and aerosol delivery systems are among the most technically complex in the medical field. They must deliver precise doses of medication, operate safely under variable conditions and meet strict regulatory requirements.

Producing these devices manually is not just slow; it introduces risk. Variations in fill volume, assembly torque or sealing integrity can compromise product performance. Automation, when designed with intelligence and experience, removes those risks while maintaining the highest throughput and repeatability.

SP Automation & Robotics has spent years refining automation solutions that handle delicate materials and complex assemblies with care. Whether the challenge is controlling micro volumes of powder or inserting canisters with consistent alignment, SP’s systems perform with the calm precision of a skilled craftsman, but at industrial speed.

Proven Expertise Across Respiratory Manufacturing Processes

SP Automation & Robotics brings a full spectrum of capability to respiratory automation. Its expertise covers every stage of the process, assembly, powder filling, packaging and canister handling, each one designed for medical-grade performance and validated to the highest standards.

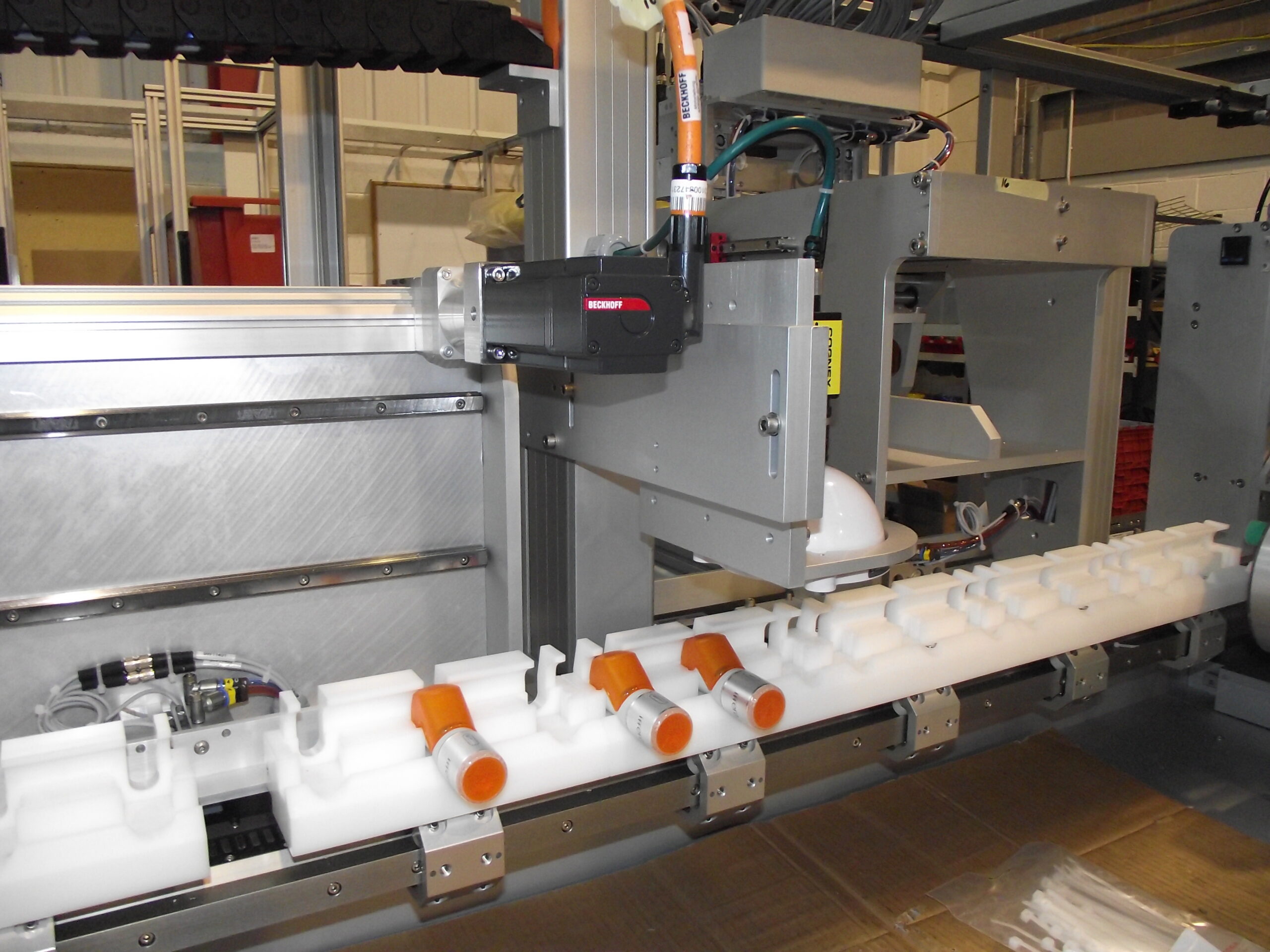

In assembly automation, SP develops solutions that handle multiple miniature components such as valves, actuators, dose counters and sealing rings. Robotic stations position and secure each element with precision that human hands cannot match. Optical sensors and vision systems confirm alignment, integrity and fit before parts progress downstream.

In powder filling applications, SP designs systems that combine gentle handling with exact volumetric or gravimetric control. These systems maintain a sterile or controlled environment to ensure product purity while using high accuracy dispensing technologies to deliver consistent dose weights. When required, SP integrates automated weighing, inspection and feedback loops that adjust for even the smallest deviations, maintaining absolute consistency throughout production.

Packaging forms the final layer of reliability. SP Automation & Robotics builds automated packaging systems that protect delicate respiratory products from contamination while maintaining traceability. Each package can be printed, inspected and sealed automatically. Vision systems verify labelling accuracy and readability, ensuring compliance with medical regulations and customer expectations.

Even the removal and replacement of canisters a seemingly simple process, requires finesse. SP has developed automated solutions that remove pressurised canisters safely, without damaging surrounding components, and reinsert them with precision. These systems handle variability in component tolerances with adaptive grippers and intelligent force control. The result is smooth operation, zero product loss and complete assurance of fit and function.

The Advantage of Experience

Experience matters deeply in medical automation. The standards are unforgiving, and there is no margin for error. SP Automation & Robotics has delivered multiple successful respiratory automation systems for global clients, each one uniquely tailored yet sharing the same foundation of excellence.

SP’s engineers understand the intricate interplay between product design, regulatory compliance and manufacturability. They know how powder behaves under different humidity conditions, how adhesives cure under specific wavelengths, and how to handle lightweight plastic parts without generating static or deformation.

This knowledge ensures that every SP system is not only technically advanced but also practical and dependable on the factory floor. It is automation engineered with empathy for the end user, both the operator who runs it and the patient who ultimately depends on its output.

Scalable Systems from Development to High Volume

Respiratory products often begin in low-volume pilot runs before scaling to mass production. SP Automation & Robotics designs every system with scalability in mind. A pilot system can validate powder dosing or assembly sequences, and that same design can then expand into a full production line through modular replication.

This approach minimises development time and cost while ensuring process continuity. The result is a smooth transition from clinical-scale manufacture to commercial supply. Each module remains accessible, maintainable and adaptable, giving manufacturers long-term flexibility as product variants or new regulations emerge.

With more than four decades of expertise in designing and manufacturing automated solutions for repertory devices, SP has built a strong foundation of transferable knowledge. However, new products driven by market shifts often require fresh approaches. This is where SP’s client partnerships truly come into their own.

When emerging devices call for innovative processes, SP collaborates closely with clients to understand the manual workflows used during clinical trials. Together, they refine and develop proof-of-concept (POC) systems that validate key aspects such as assembly methods. These early-stage insights enable SP to design robust, full-scale automation solutions, with the POC phase significantly reducing technical and operational risk.

Precision Engineering Meets Intelligent Automation

The secret to SP’s success in respiratory automation lies in integration. Precision engineering forms the backbone, but intelligence drives the process. Data capture, traceability and real-time analytics are embedded into every system.

Sensors monitor environmental conditions, dosing parameters and assembly accuracy. If a deviation occurs, the system reacts instantly, adjusting, rejecting or alerting before a single faulty product proceeds. Every movement is recorded, creating a full digital history for each unit produced.

For manufacturers, this level of visibility is transformative. It enables predictive maintenance, process optimisation and complete regulatory confidence. For patients, it ensures that every inhaler, every dose and every breath meets the highest standards of safety and performance.

In addition to embedded monitoring systems, SP incorporates a high-powered vision system to inspect respiratory devices as they are being processed. These inspections have included counter inspection, assembly, label position accuracy and even mould defects.

Sustainability and Efficiency in Medical Manufacturing

Sustainability is no longer optional in healthcare production. SP Automation & Robotics designs systems that not only meet efficiency targets but actively reduce waste and environmental impact.

By automating powder handling, SP minimises spillage and airborne particulates. Automated inspection prevents defective parts from reaching downstream stages, eliminating unnecessary rework. Smart control systems optimise energy use and machine uptime, reducing both cost and carbon footprint.

This commitment to sustainable automation aligns with SP’s wider philosophy: build solutions that protect both people and the planet, delivering long-term value for customers and society.

Partnership Beyond Installation

Automation in the medical sector is not a one-time project; it is an ongoing partnership. SP Automation & Robotics supports clients at every stage of the journey, from concept and design through validation, training, and aftercare.

SP’s service teams provide ongoing optimisation and process refinement, ensuring systems continue to meet performance goals even as products evolve. Whether introducing new powder formulations, changing packaging materials or increasing throughput, SP’s engineers help adapt systems smoothly without downtime or disruption.

This enduring collaboration builds trust. Clients know that SP will not simply deliver a machine; it will deliver a relationship dedicated to long-term excellence.

Confidence Built on Precision

Every movement in a respiratory automation system matters. Every seal must hold, every fill must measure correctly, and every canister must align flawlessly. SP Automation & Robotics brings confidence to each of these critical moments.

The company’s track record in respiratory device assembly, packaging, powder filling and canister handling, demonstrates a rare combination of technical mastery and real-world reliability. For SP, precision is not just about accuracy; it is about assurance, the assurance that every product leaving the line is as perfect as the first.

Conclusion

In respiratory manufacturing, the stakes could not be higher. A patient’s well-being depends on consistent performance, and manufacturers need systems they can trust completely. SP Automation & Robotics delivers that trust.

With proven experience, modular scalability and a deep understanding of medical manufacturing, SP continues to shape the future of respiratory automation. From concept to commercialisation, SP ensures that every process is robust, compliant and ready to perform.

Follow us on LinkedIn to stay updated.

Read more about our automation here…

- Benefits of Automation

- Feeding & Handling Automation

- Automated Medical Device & Assembly Systems

- Medical Device Material

- Part Handling and Part Feeding Vibratory Bowl

- Cost of Industrial Automation

- Advantages & Disadvantages of Robotic Automation

- Medical Device Automation

- Bowl Feeder vs. a Vision Guider Feed System

- Special Purpose Machinery

Contact Us

More information

Here you can find the most important news, blogs and videos from SP Automation & Robotics.. We will highlight developments, insightful industry trends, company announcements, technology expos, conferences, and events.