Laser Welding in Automation: How SP Automation & Robotics Fuses Precision, Speed and Reliability

Topics:

November 2025

In the high-stakes world of modern manufacturing, the smallest joint often carries the greatest responsibility. Whether in medical devices, electronics or precision instruments, every connection must withstand pressure, time and scrutiny. Laser welding, with its unmatched control and clean precision, has become the gold standard for achieving those connections.

At SP Automation & Robotics, laser welding is more than a technology, it is an art of fusion where light becomes a tool of reliability. SP designs and integrates automated laser welding systems that deliver consistent, high-quality welds on even the most intricate assemblies. For manufacturers seeking the perfect blend of speed, precision and repeatability, SP’s expertise transforms what was once a complex process into a seamless, measurable and dependable one.

The Science of Light, Engineered for Production

Laser welding uses a concentrated beam of light to melt and join materials with extraordinary precision. Unlike traditional welding techniques, it requires no filler materials, produces minimal distortion and delivers incredibly narrow, clean seams. This makes it ideal for delicate or miniaturised components, exactly the kind of assemblies found in medical devices, sensors and fine electronics.

SP Automation & Robotics harnesses this science of light and translates it into automation. Its systems bring together advanced robotics, high-performance laser sources and intelligent control software to deliver welds with accuracy down to fractions of a millimetre. Each system is built around the specific geometry, materials and tolerances of the client’s product, ensuring optimal beam alignment and weld penetration.

What sets SP apart is not just its technical command of laser welding, but its ability to integrate the process into complete automated production lines. The laser becomes a stage within a larger choreography of feeding, alignment, welding, and inspection, all harmonised under a single control architecture and machine.

Selection of Laser Sources

The type of precision laser welding equipment used in our automated machines is dictated by material compatibility, joint geometry, and required weld strength. In some instances, Plastics may require ultrasonic or infrared laser systems, while stainless steel welded to carbide often needs high-energy fibre or Nd:YAG lasers for strong, localised bonds. We also have to consider thermal sensitivity, reflectivity, and thickness, all of which guide the choice of laser type.

Other major influencers are production speed, automation level, and weld repeatability, which all dictate which precision welding technology is most suitable. At SP Automation & Robotics, we utilise our laser welding partners and derisk the project by conducting trials at the proposal stage to ensure the solution is fit for purpose.

Laser Welding in the Surgical Probe Assembly Line

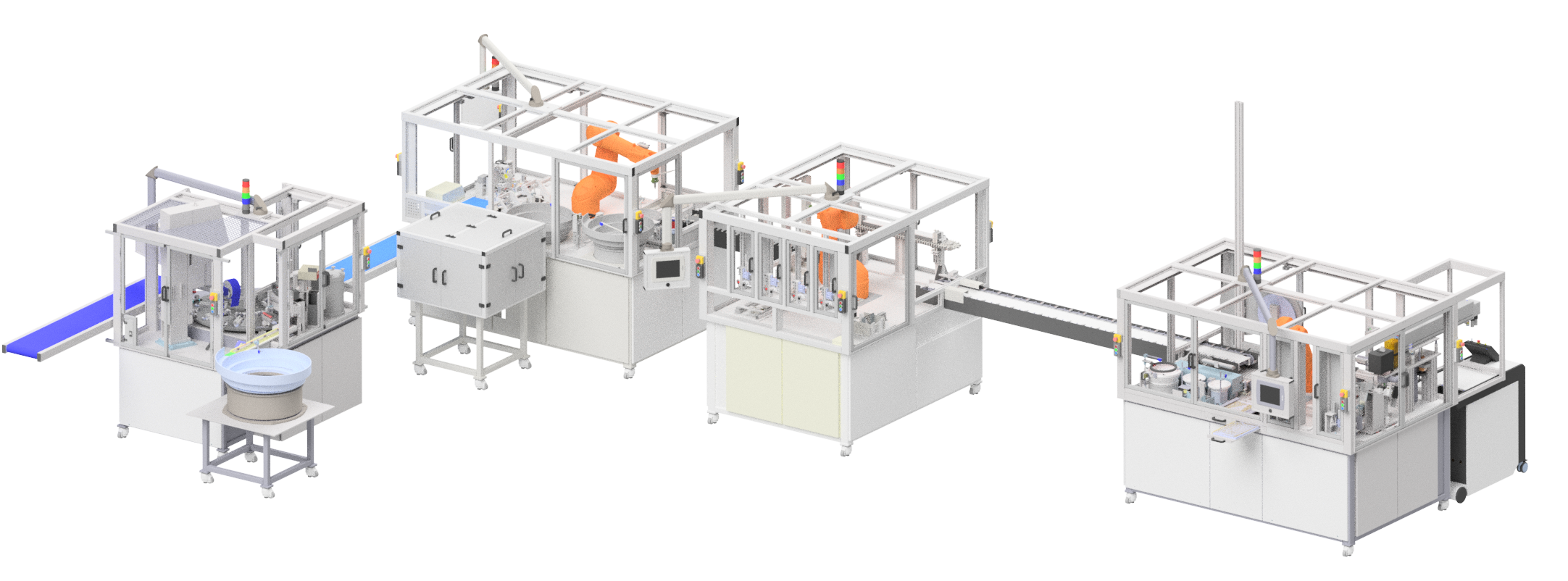

One of the most striking examples of SP Automation & Robotics’ capabilities is found in its Surgical Probe Assembly Line, designed and built for a leading medical device manufacturer. This fourteen-metre-long modular production line showcased SP’s full spectrum of expertise, from robotics to laser welding and UV adhesive curing.

In the first module of this system, laser welding played a crucial role in joining the stainless-steel tubes, carbide components and fine control wires that formed the core of the surgical probe’s structure. The challenge was formidable: each weld needed to deliver both mechanical strength and precision alignment, all within cycle times measured in seconds.

SP Automation & Robotics engineered a fully automated cell that utilised a six-axis Stäubli robot to precisely position components under the laser head. The beam parameters were tuned to prevent overheating of sensitive materials while still ensuring a robust, hermetically sealed weld. Real-time monitoring and vision verification guaranteed that each joint met exact dimensional and visual standards.

The result was a flawlessly consistent process capable of producing fully assembled surgical probes every twenty-five seconds. The precision of the laser welds ensured not only mechanical integrity but also the functional reliability demanded by surgeons who depend on the device in critical operations. Again, the section of the laser was determined by an in-depth study and trials, partnering with our laser expert partners and our customers.

Why Laser Welding Matters

In today’s manufacturing landscape, the ability to weld components with microscopic precision has transformed design possibilities. Laser welding allows engineers to join metals that were once considered difficult or incompatible, including thin-walled stainless steels and complex alloys. The heat-affected zone is so small that surrounding materials retain their original properties, a crucial factor for assemblies containing sensors, electronics or delicate plastics.

SP Automation & Robotics integrates laser welding wherever precision, cleanliness and repeatability are non-negotiable. For medical devices, that means welds that meet biocompatibility standards without secondary cleaning or polishing. For electronics, it means hermetic seals that protect sensitive components from contamination. For all sectors, it means consistent quality without compromise.

Automation that Perfects Every Weld

The difference between a good weld and a perfect weld often lies in control and control is what SP Automation & Robotics does best. By combining robotics with laser welding, SP creates systems where positioning accuracy and process repeatability are guaranteed.

The robots handle parts with sub-millimetre precision, ensuring the laser interacts with the material exactly as intended every time. Advanced sensors monitor focus, temperature and alignment to ensure that the process adapts in real time. Vision systems confirm weld accuracy, while automated calibration maintains consistency across long production runs.

This intelligent automation transforms laser welding from a manual art into a reproducible science. It eliminates human variability, minimises waste and accelerates throughput without sacrificing quality. The result is a process that manufacturers can depend on shift after shift, year after year.

The Business Benefits of Laser Welding Automation

Precision is valuable, but in manufacturing, value is measured by more than accuracy. SP Automation & Robotics understands that its clients need measurable returns, faster cycles, higher yield and lower cost per part.

Laser welding automation delivers exactly that. The speed of laser fusion means joints can be completed in milliseconds, allowing for high-volume production without heat distortion or rework. The non-contact nature of the process reduces tool wear and maintenance costs. The cleanliness of the weld eliminates the need for post-processing, saving both time and resources.

For the surgical probe line, these advantages translated into a dramatic improvement in output and reliability. The modular construction of the system also allowed easy access for maintenance and expansion, ensuring the line could adapt to future variants without costly redesigns.

Sustainability Through Precision

Sustainability in manufacturing is increasingly tied to efficiency and few processes are as efficient as laser welding. By using concentrated energy exactly where it is needed, it minimises waste, consumes less energy and generates no consumables such as filler wire or flux.

SP Automation & Robotics designs its laser welding systems to operate with energy efficiency in mind. Reduced rework, minimal material waste and optimised process control all contribute to a lower carbon footprint. In regulated sectors such as medical manufacturing, where sustainability and compliance often go hand in hand, this efficiency is both an ethical and commercial advantage.

Traceability and Quality Control

No high-precision process is complete without documentation and traceability. SP Automation & Robotics integrates advanced monitoring and data logging tools into its laser welding systems. Parameters such as laser power, exposure time, joint alignment and weld integrity are captured and stored automatically.

This not only ensures quality assurance during production but also provides an auditable record for regulatory compliance. When paired with SP’s inspection and testing modules, the system forms a closed-loop feedback environment where quality is continuously verified, not just sampled.

From Challenge to Confidence

Every SP Automation & Robotics project begins with a challenge, an engineering problem that requires a solution as unique as the product itself. With laser welding, that often means balancing the competing demands of strength, speed and delicacy.

Through decades of experience, SP’s engineers have learned how to tailor beam power, focus and motion to meet the exact characteristics of each material. They know when to apply pulsed lasers for fine micro-welds, when to use continuous-wave systems for deeper penetration and how to align robotic motion to complex component geometries.

The outcome is always the same: confidence. Manufacturers know that when SP Automation & Robotics is behind their laser welding process, every joint will meet specification, every time.

Innovation That Evolves with You

Technology moves fast, but SP Automation & Robotics designs systems that move faster. As laser sources, optics and sensor technologies evolve, SP ensures its systems remain upgradeable and future-ready. The modular design philosophy means that clients can introduce new laser heads, additional robots or enhanced inspection tools without replacing the entire system.

This adaptability transforms automation from a static investment into a living asset that grows with the business. It reflects SP’s broader philosophy: build today for what tomorrow will demand.

The Fusion of Light and Intelligence

Laser welding is where physics meets craftsmanship, where energy becomes precision and where SP Automation & Robotics’ commitment to engineering excellence shines brightest. It represents the company’s belief that automation should not merely replicate human skill but elevate it, making every process faster, cleaner and more reliable than ever before.

For manufacturers who demand the highest levels of consistency, quality and flexibility, SP’s automated laser welding solutions deliver measurable results. From the delicate assembly of surgical probes to complex industrial components, SP brings light to the art of manufacturing perfection.

Because in the hands of SP Automation & Robotics, every beam of light becomes a bond of confidence.

Follow us on LinkedIn to stay updated.

Read more about our automation here…

- Benefits of Automation

- Feeding & Handling Automation

- Automated Medical Device & Assembly Systems

- Medical Device Material

- Part Handling and Part Feeding Vibratory Bowl

- Cost of Industrial Automation

- Advantages & Disadvantages of Robotic Automation

- Medical Device Automation

- Bowl Feeder vs. a Vision Guider Feed System

- Special Purpose Machinery

Contact Us

More information

Here you can find the most important news, blogs and videos from SP Automation & Robotics.. We will highlight developments, insightful industry trends, company announcements, technology expos, conferences, and events.