Industry 4.0 & COBOTS

October 2017

Roy Henderson, managing director at SP Automation & Robotics, a leading automation specialist, looks at what has changed during his 30+ years in the business and where this trend is heading:

Since the Industrial Revolution in the late 1700s, the change in our factories has been immense. We are entering our fourth industrial revolution; Industry 4.0 is the name for this current trend. But what does it actually mean?

“With each new decade comes a desire to do more with less. This is progress. This means that I stream my music rather than twist the arm on a gramophone; it is the beep to indicate a wall when reversing my car, the froth on my cappuccino or my electric toothbrush. It is everyday life in a developed world, and it is what makes what we do great.

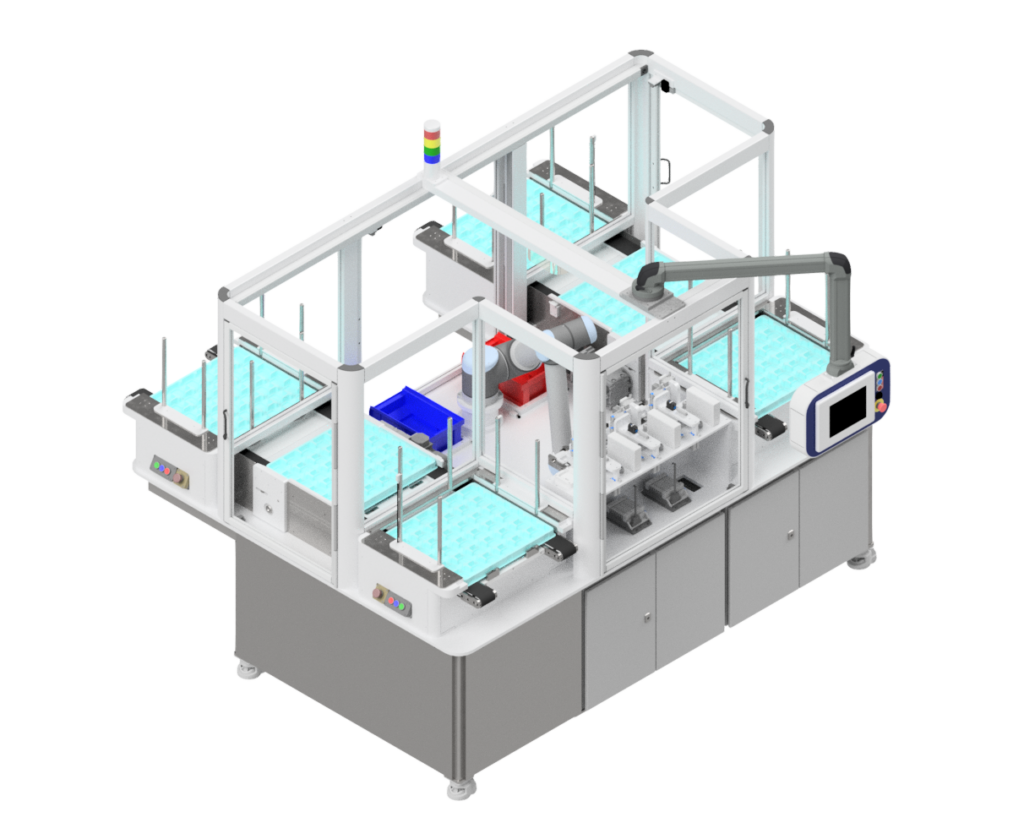

I work with robots. Actually, I work with a small team of highly skilled designers and engineers who make robots. These robots are automated solutions that enable progress – everything from cappuccino froth to electric toothbrushes – that play a very important part in this modern-day industrial revolution, or Industry 4.0. I’ve also heard this progress described as a “smart factory”. This describes what we do very well. We design smart solutions to specific problems.

Industry 4.0 is made up of many segments, including artificial intelligence, machine learning, the internet of things and the introduction of robots and humans working alongside one another, known as “cobots”.

This isn’t as wild as it sounds! Cobots are not Jetson-like robots that wear an apron and spin about your kitchen, nor are they baby dolls that mimic the sounds and smells of a real child. These are machines that enable low-skilled labour workers to reduce highly repetitive, mundane tasks. They open the opportunity for promotion to higher positions that require less physical effort and jobs that are more rewarding and better paid.

Employees working alongside robots (or cobots) can be extremely sensitive to force torque, allowing the cobot to automatically stop when its human counterpart intrudes within set parameters. The cobot can also have a positive impact on the reduction of repetitive strain injuries and lifting injuries. One of my first projects at SP Technology, following the completion of my toolmaker apprenticeship in 1992, was the design of such a solution.

This was my first opportunity as a toolmaker apprentice to experience the design side of the business. Understanding how a design will go from a drawing board (using a pencil, paper, set square and calculator) to the factory floor is still a crucial part of our service. Breaking down the individual parts of the assembly to understand how and why they work together is key to an effective solution. My first attempt at this was to design a small swaging press system that would replace a series of four-tonne presses that shaped a suture and needle together (used in surgical operations). The original machines were very big and noisy, and due to the product needing to be rotated during shaping, the operators were continually complaining of repetitive strain injury (RSI).

After discussing the problems and understanding our customers’ concerns, I designed a very small self-contained unit. I remember conducting trials to determine the actual force required and

After some field trials and modifications, the unit went into production. We eventually produced over 300 of these units and shipped them to pharmaceutical companies worldwide. This small but effective solution was born out of inventive thought using real data to overcome a problem. Industry 4.0 is the next stage to measure how our inventions perform in the real world, to allow us to make decisions based on facts. We are now less likely to calculate using only our brains when designing, as software design packages enable us to develop our thoughts further and faster.

This is a type of robot, or cobot, that enables the human workforce to undertake a vital step in a process that would otherwise cause repetitive strain injury to humans. This solution enhanced the experience of the worker and, ultimately, the productivity of the factory.

Industry 4.0 will not replace humans. At SP Technology, our work with humans is just as important as our work with machines. Understanding what challenges our customers face and how the introduction of robotics and automated solutions can allow a more effective approach will safeguard jobs and allow the progress we all crave. Whether it is enjoying a cappuccino, safely reversing our car or streaming music, we choose to embrace this progress in our solutions for smart factory automation.

As we begin to research and embrace Industry 4.0, the benefits are potentially huge. Advancements in how information in products and services can be exchanged, to using high-powered analytics to measure the effectiveness of our workplace and manufacturing, are providing big data to validate and progress our ideas. Even with the example of a simplistic automation solution above, SP Automation & Robotics has always used data to make decisions. Industry 4.0 helps us as manufacturers of automated solutions to quickly analyse problems and even predict them, pushing AI (artificial intelligence) to the next level.”

Follow us on LinkedIn, Twitter & Facebook to stay updated

Read more about our automation here…

- Benefits of Automation

- Feeding & Handling Automation

- Automated Medical Device & Assembly Systems

- Medical Device Material

- Part Handling and Part Feeding Vibratory Bowl

- Cost of Industrial Automation

- Advantages & Disadvantages of Robotic Automation

- Medical Device Automation

- Bowl Feeder vs. a Vision Guider Feed System

- Special Purpose Machinery

Contact Us

More information

Here you can find the most important news, blogs and videos from SP Automation & Robotics.. We will highlight developments, insightful industry trends, company announcements, technology expos, conferences, and events.