How to Reduce Manufacturing Downtime with Fast Changeovers and Automation

Topics:

October 2025

Downtime is the invisible profit thief of manufacturing. It creeps in quietly during every changeover, stealing production time, limiting flexibility and piling up costs that no business wants to see. In a world driven by rapid product variation, stricter regulations and customers who expect fast delivery, reducing downtime is not merely desirable. It is critical for market survival. This is why fast changeovers have become a game-changing priority across the manufacturing landscape. And with SP Automation & Robotics at the forefront of automation design, manufacturers can now turn changeovers into an advantage rather than an unavoidable obstacle.

Fast changeovers are the heartbeat of agile production. They allow manufacturers to transition smoothly from one product type to another without disrupting workflow or compromising output. While many businesses recognise the value of automation in speeding up cycle times, fewer understand the dramatic impact automation can have on the downtime between runs. When systems are rigid and difficult to modify, production can feel like a high-speed motorway… until the moment you hit a five-mile traffic jam. SP Automation & Robotics builds solutions designed to keep operations moving, eliminating unnecessary bottlenecks and transforming delays into near-seamless transitions.

Manufacturing doesn’t stand still, and SP Automation & Robotics believes that automation shouldn’t either. By designing flexibility into each machine, SP ensures that businesses have the option to adapt quickly, pursue new market opportunities and stay ahead of shifting consumer demands. With fast changeovers built into the design DNA, production no longer pauses for change. It evolves.

What Causes Downtime During Manufacturing Changeovers?

Changeovers often involve far more than simply swapping out a tool or adjusting a jig. They require reconfiguring stations, validating equipment, updating product recipes, resetting safety checks and recalibrating precise control parameters. When these elements depend heavily on manual labour or outdated processes, delays are inevitable. A single misalignment can trigger hours of troubleshooting. A missing part can cause a cascading halt to the schedule.

SP Automation & Robotics understands these pain points intimately. Years of engineering advanced automation systems have shown that downtime stems not from change itself, but from poorly designed changeovers. When a system forces operators to become detectives searching for the right tools or engineers repeatedly fine-tuning positions, productivity dissolves into frustration. The downtime problem emerges long before the first stop button is pressed. It begins when flexibility isn’t given priority during design.

How Automation Enables Fast Changeovers

With intelligent engineering, changeovers transform from chaotic events into smooth and reliable operation. SP Automation & Robotics builds adaptable automation platforms where tooling, fixtures and components can be switched quickly and accurately. Modular design ensures processes can be repeated with the same alignment every single time, removing uncertainty and eliminating trial-and-error adjustments.

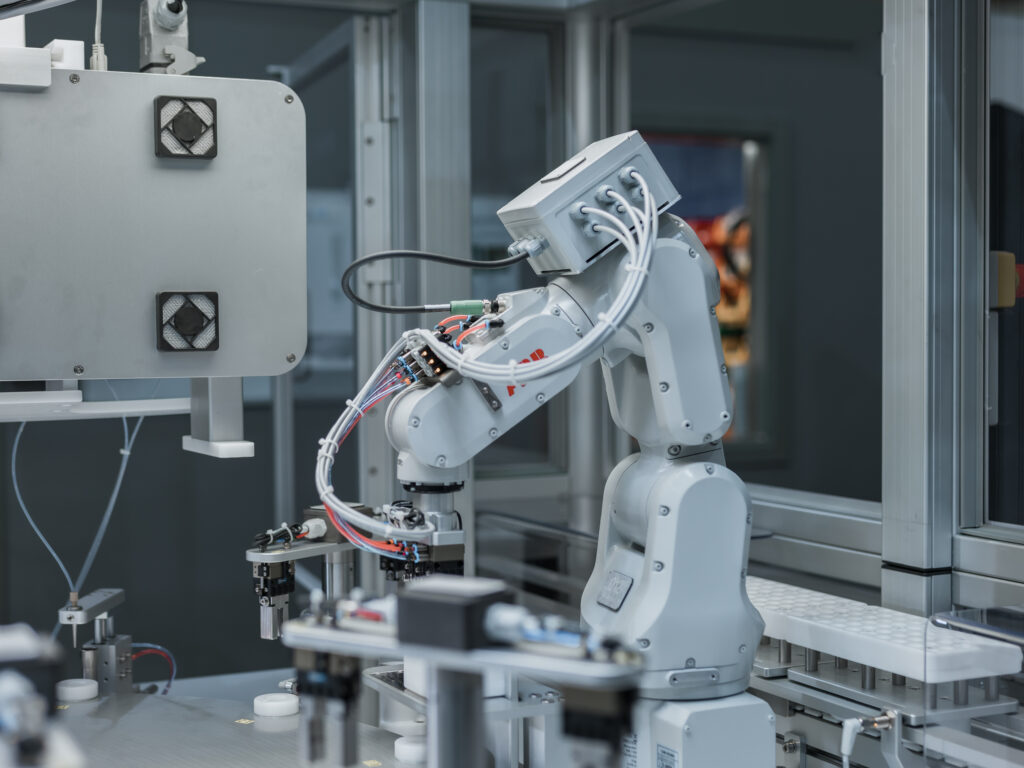

Robotics plays a vital role as well. When a robotic system can handle different parts, packaging formats or batch sizes with minimal reconfiguration, production can accelerate confidently. Smart vision systems, automated calibration and intuitive operator interfaces support rapid verification that everything is ready. The result is a line that restarts not in minutes, but moments.

SP Automation & Robotics also integrates software tools that streamline changeovers at the digital level. Recipe management, data logging and electronic line clearance help control the changeover as a guided, auditable flow. Compliance becomes quicker, safer and more accurate. There’s no slowing down to gather paperwork or triple-check settings. The automation takes responsibility for precision.

True fast changeovers extend beyond mechanics. They are a partnership between digital intelligence and dynamic motion. SP Automation & Robotics brings these elements together so that manufacturers aren’t merely automated, but optimised.

An Example of Fast Changeovers

Future-proofing your automation must begin at the design stage. At SP Automation & Robotics, we work closely with clients to ensure all requirements are fully understood, both current and anticipated future product variations.

For example, the system shown below was developed to handle two different products, with a maximum tooling changeover time of just 10 minutes. The solution incorporated a dual-nested linear indexing system capable of “half indexing” between product nests. This allowed two product nests to be presented to the operating stations simultaneously. Without this approach, a full nest changeover would have taken approximately two hours.

Feed systems were engineered with quick-change guiding mechanisms, while orientation stations featured pneumatic and servo-driven positioning to accommodate both product sizes.

The result was a highly flexible system capable of switching to the second product simply by swapping out quick-change tooling and selecting the new product on the HMI, which automatically adjusted the necessary tooling settings.

As technology has evolved, SP has integrated intelligent transport systems such as Beckhoff’s XTS and XPlanar, taking process and product changeovers to a new level. These systems enable tooling to move freely to an almost unlimited number of positions, delivering unprecedented flexibility and efficiency.

The Business Impact of Reducing Changeover Time

Every minute saved in changeover equals more uptime. More uptime equals more production. And more production equals greater profitability. That equation has been true for decades, but in today’s competitive climate, the financial significance is amplified.

Manufacturers who implement fast changeover automation from SP Automation & Robotics benefit from stronger operational stability. Instead of planning fewer, longer runs to avoid changeovers, they can execute more frequent transitions that support product variety and demand responsiveness. Innovation becomes easier because new product introductions no longer require long interruptions or unmanageable cost implications. Companies gain the courage to experiment, test and launch because the line can adapt swiftly without draining budgets.

There is also a powerful human advantage. When automation removes repetitive and technically demanding adjustments, skilled workers shift their focus toward continuous improvement, maintenance and quality. Team morale strengthens when changeovers aren’t dreaded disruptions but smooth and controlled activities. The entire workforce operates with greater confidence and clarity.

Sustainability rises alongside efficiency. Reduced scrap during transitions and lower energy usage during downtime contribute meaningfully to environmental goals. SP Automation & Robotics helps manufacturers reduce waste not only in material form but in time, energy and talent.

Even regulatory oversight becomes simpler. Many industries rely on validated configurations, traceability and strict production parameters. With automated checks designed by SP Automation & Robotics, compliance becomes embedded in the process rather than an afterthought that adds delays.

Why SP Automation & Robotics Leads in Flexible Changeover Design

SP Automation & Robotics never takes a static approach to automation. Instead, each system is thoughtfully designed for the future as much as for the present. Customers often enter automation projects knowing what they produce today, but not always what tomorrow may demand. SP prepares manufacturers for that tomorrow.

By working closely with clients from concept to commissioning, SP engineering teams ensure every flexibility requirement is understood and designed intentionally. Quick-release mechanisms, automated positioning, adaptable tooling and intuitive controls all blend into a solution that evolves with the business.

Where some automation suppliers build machines that operate efficiently but struggle to pivot, SP Automation & Robotics creates systems that thrive on adaptability. That is what change-ready automation looks like: mechanisms and software that transform without hesitation, ensuring productivity never stumbles.

SP’s fast changeover solutions aren’t just technical features. They are strategic business assets. Their value compounds over time as market opportunities shift, product ranges expand and competitive pressures intensify.

How Fast Changeovers Support Future Manufacturing Growth

Manufacturing is moving from mass production toward mass customisation. Customers expect choice. Product life cycles continue to shrink. Market shifts occur without warning. In this dynamic landscape, flexibility defines winners. Fast changeovers power that transformation.

SP Automation & Robotics gives manufacturers the freedom to pursue new SKUs, new designs and new markets with confidence that operations will keep pace. Rather than fearing disruption, companies equipped with fast changeover automation embrace change as a growth engine.

The most resilient organisations in the coming decade will be those able to reinvent quickly and efficiently. Downtime will separate innovators from those who fall behind. By reducing the gap between one production run and the next, SP Automation & Robotics removes barriers to agility and positions its clients to compete at the highest level.

Manufacturers who look at their automation lines and ask, “What else could we make if we could switch faster?” will unlock enormous potential. The answer, powered by SP, is: almost anything.

A Future Where Change Is Seamless

With SP Automation & Robotics as a trusted partner, changeovers shift from being a necessary interruption to a competitive advantage. The line no longer waits. It responds. It adapts. It anticipates. It stands ready for what’s next.

Manufacturing success relies not only on speed during production, but on speed during transformation. That is the true measure of high-performance automation. And with SP Automation & Robotics designing systems that minimise downtime and maximise profitability, manufacturers gain more than equipment. They gain momentum, resilience and strategic edge.

In a world where every second counts, the smartest businesses make sure none go to waste. Fast changeovers are the key that unlocks unstoppable progress, and SP Automation & Robotics is the partner that ensures change always drives growth rather than delay. As previously mentioned, utilising new technology such as Beckhoff’s intelligent transport systems means machine concepts can now incorporate very quick changeovers and provide future-proofing for your automation projects.

Follow us on LinkedIn to stay updated.

Read more about our automation here…

- Benefits of Automation

- Feeding & Handling Automation

- Automated Medical Device & Assembly Systems

- Medical Device Material

- Part Handling and Part Feeding Vibratory Bowl

- Cost of Industrial Automation

- Advantages & Disadvantages of Robotic Automation

- Medical Device Automation

- Bowl Feeder vs. a Vision Guider Feed System

- Special Purpose Machinery

Contact Us

More information

Here you can find the most important news, blogs and videos from SP Automation & Robotics.. We will highlight developments, insightful industry trends, company announcements, technology expos, conferences, and events.